sales@1machinery.com

|

|

+1-819-346-2369 sales@1machinery.com |

Specifications

| Ask for quotation | |

| Stock ref. # 1318 |

|

|

Other specifications

Giddings & Lewis HMC-410 CNC Horizontal Machining Center YEAR: 2003 Spindle Taper #50 ANSI B5.50 AC Variable Speed, Brushless, Digital Spindle Drive Spindle speed range . .... 10 - 6000 RPM S6-40% Power Rating 45 kW (60 HP) Continuous Power Rating .. 37 kW (50 HP) Pallet size ............. 1600 x 1250 mm (62.9 x 49.2) Pallet Load Capacity- (centrally located) ... 7000 kg (15,430 lb) Work Zone Diameter ....................... 2500 mm (98.4) Work Zone Height........................................................................ 2000 mm (78.7) Machine Features Automatic Linear Pallet Changer System with Two (2) Load/Unload Stations 85 Second Pallet Change Cycle 360,000 Position Rotary Table Two (2) 1250 mm x 1600 mm Pallets with T Slots and a Precision Center Bushing 60 Position Automatic Tool changer 20 Second Chip-to-chip Tool Change Cycle Dual X-Axis Chip Conveyors with Elevator Flood Coolant Coolant Thru-The-Spindle - 17 BAR (250 PSI) Coolant System Equipped with a Dual Bag Filtration System Coolant Reservoir Capacity 1,200 l (317 gal) Part Wash Cycle Stainless Steel Way Covers X, Y and Z axes Heavy Duty Roller Linear Guide ways Automatic Central Lubrication System Hydraulic System Chip and Coolant Enclosure with Roof Operator Platform/Walkway inside Chip and Coolant Enclosure Axis Feedback Distance Coded Heidenhain Linear Scale Feedback on X, Y and Z Axes Encoder Feedback; B axis Control System SIEMENS SINUMERIK 840D High Performance CNC Computer Numerical Control with 10. 4 Color Display 2.5 Mbyte Minimum of CNC User Memory for Part Programs and Tool Offsets 2.2 Gbyte Minimum Hard Drive Rigid Tapping High Level Programming capability (Variables and Parameters) Refer (CMC 840D) Control Specification Attached for Details. Two (2) RS 232 Data Interface Boards Travel Ranges X Axis (Longitudinal) .... 3000 mm (118.1) Y Axis (Vertical) ................... 2100 mm (82.6) Y Minimum from pallet Surface to spindle centerline........................ 0 mm (0") Z Axis (Depth) . .................. 1800 mm (70.8") Z Minimum from pallet centerline to spindle face............................. 300 mm (11.8") Positioning Performance per ANSI 5.54 Standard, Unidirectional Data X, Y & Z Axes Positioning Accuracy (Any 1525 mm (60) length)............................ 0.005 mm (.0002) Positioning Repeatability................................................................... 0.0025 mm (.0001) B Axis Positioning Accuracy .......................................................... 10 Arc Seconds B Axis Positioning Repeatability....................................................... 3 Arc Seconds Positioning Performance per ANSI Standard, Bi-directional Data X, Y & Z Axes Positioning Accuracy A..................................................................... 0.008 mm (0.00032) Positioning Repeatability R............................................................... 0.005 mm (0.0002) Reversal (B)...................................................................................... 0.005 mm (.0002) B Axis Positioning Accuracy (A)....................................................... 10 Arc Seconds B Axis Positioning Repeatability (R).................................................. 5 Arc Seconds B Axis Reversal (B)........................................................................... 3 Arc Seconds Contouring Rotary Table Index Positions........................................................................... 360,000 in .001 deg. Increments Index Rate.................................................................................. 6 RPM Rotary B-Axis Feed.................................................................... /Min., / Rev. Or inverse Time Torque- Continuous................................................................... 14,642 N-m (10,797 Ft-lb) Traverse Rates X axis ....................................................................................... 32 m/min (1260 IPM) Y axis ....................................................................................... 32 m/min (1260 IPM) Z axis ....................................................................................... 32 m/min (1260 IPM) Acceleration/Deceleration Rate (X,Y,Z Axes) .......................... 0.3 g B axis ....................................................................................... 6 RPM Toolchanger Specifications Tool ........................................................................................... 50 Taper per ANSI B5.50 Type of Retention Knob ............................................................ ANSI B5.50 Quantity of Tools (Standard) ..................................................... 60 Maximum tool weight ................................................................ 27 Kg (60 lb) Maximum tool diameter (All pockets full).................................... 114mm (4.48) Maximum tool diameter (Adjacent pockets empty)..................... 242mm (9.5) Max. Tool length ........................................................................ 711 mm (26.0) Chip to chip toolchange time (tools under 27 kg) ...................... 20 seconds Tool to tool toolchange time (tools under 27 kg) ........................ 2 seconds Maximum moment .................................................................... 6 Kg-m (520 in. Lbs.) Electrical Equipment Electrical equipment complies with DIN electrical standards for all controls, unless stated otherwise. Compliance with national, state, and local codes that deviate from that specified may require special charges. Paint The base machine is painted standard Giddings & Lewis colors, light gray ( RAL 9002, Pantone equivalent Cool grey 2) with blue highlights (RAL 5005, Pantone equivalent 294) The Giddings & Lewis HMC 410 is a Heavy-duty Horizontal Machining Center designed for High Performance and High Productivity. With an unmatched combination of ranges, features and speed, the HMC 410 will take your large part manufacturing productivity to new levels. Slash time-wasting parasitic time with a standard 60 position automatic tool changer featuring a chip-to-chip tool change time of only 20 seconds, and with rapid traverse rates of 32 m/min (1260 in/min!) Handle your largest parts with a generous 2500 mm (98.4) diameter workzone and a 7000 kg (15,430 lb.) pallet capacity. A standard 360,000 position built-in rotary table, combined with a two (2) position automatic pallet changer and a full enclosure, reduces setup lime and makes the HMC 410 a fully automated high-performance production center. This powerful machine also comes with an optional 130 mm (5.1") diameter live spindle headstock with 800 mm (31 .5') spindle extension. 4000 RPM spindle speed and 45 kw (60 Hp) to further maximize your manufacturing flexibility. NOTE: The former owner bought it new for $1.2 Million usd. It only has about 2000 hours on it. It is being sold because they bought the wrong machine. The only job they had for it was facing and squaring aluminum billets.

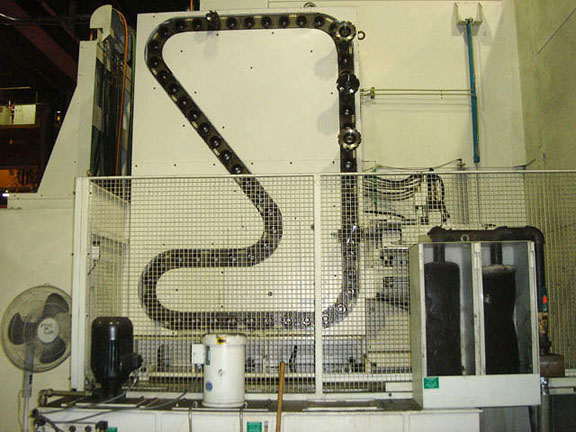

Photos

|

Machinery

Inc. |