sales@1machinery.com

|

|

+1-819-346-2369 sales@1machinery.com |

Specifications

| Ask for quotation | |

| Stock ref. # 1419 |

|

|

Other specifications

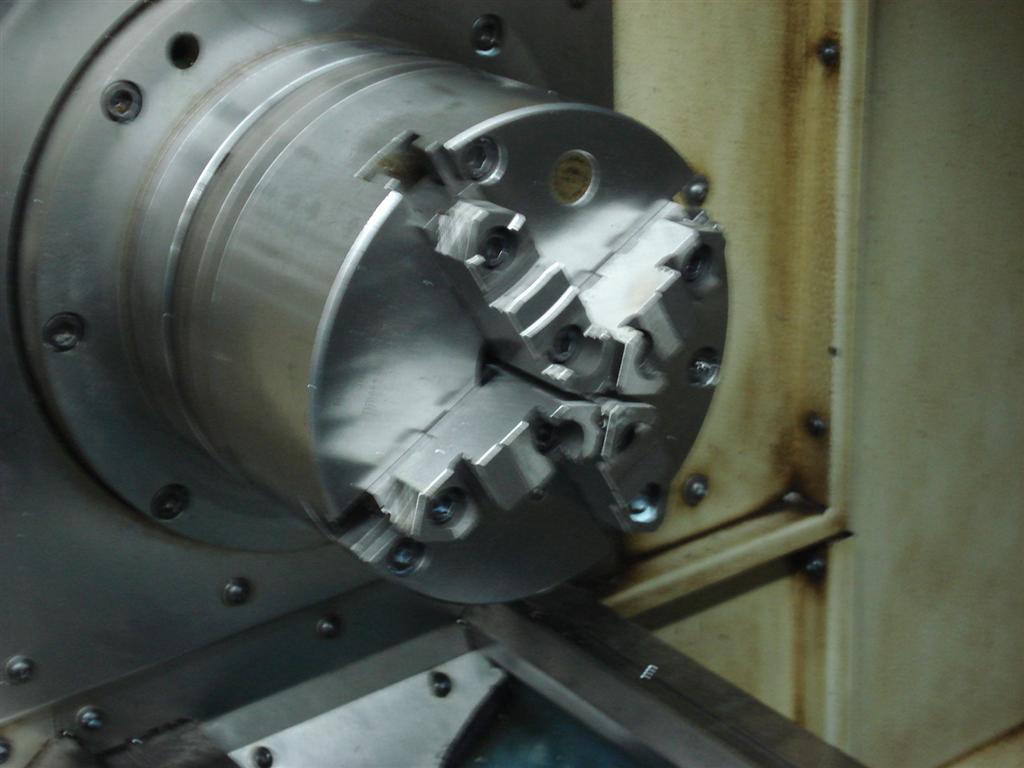

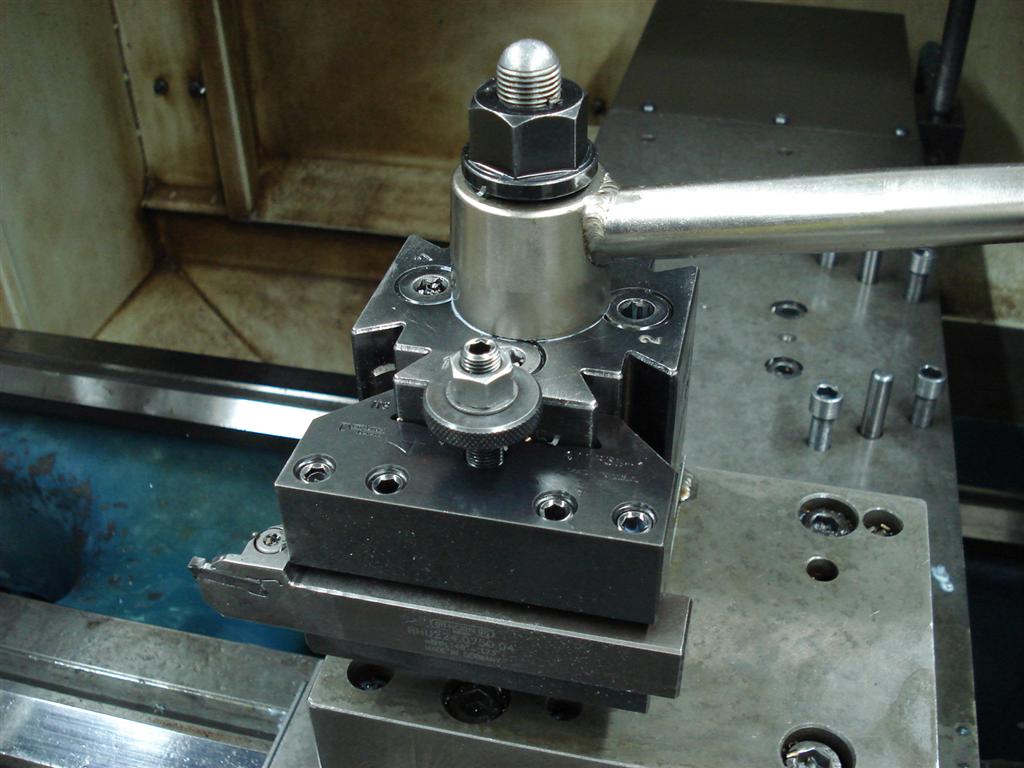

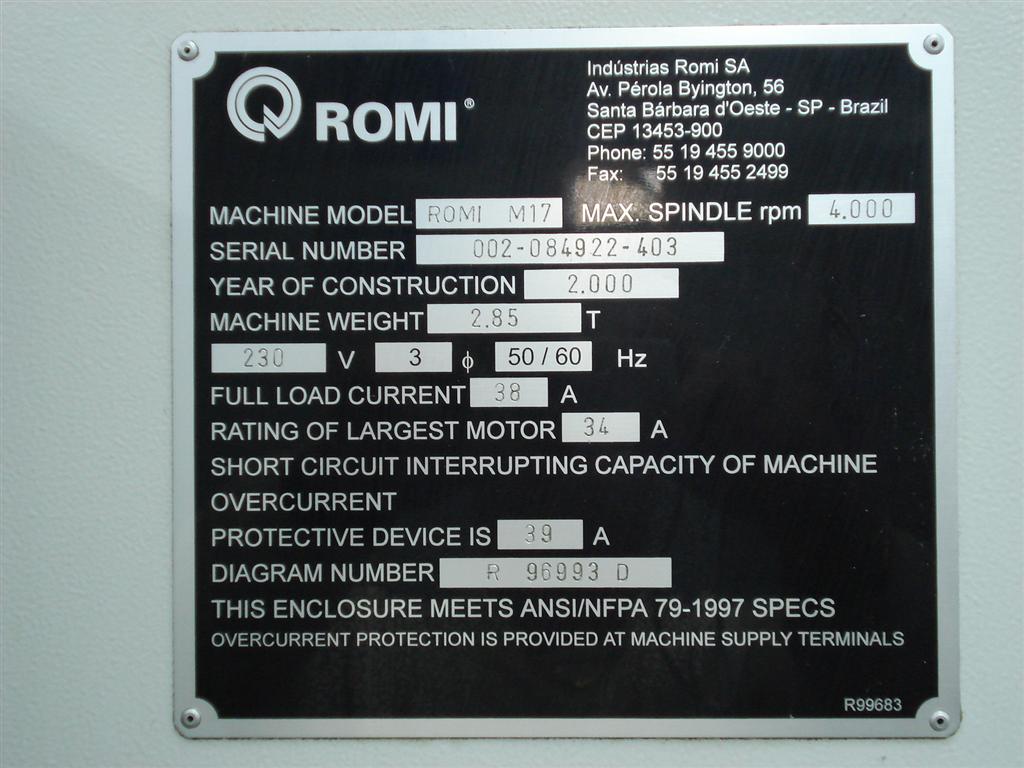

17" X 43" ROMI M17 ELECTRONIC HIGH PRECISION CNC LATHE YEAR: 2000 Swing over bed 16.93" Swing over cross slide 8.03" Distance between centers 43.46" Z axis travel 42.85" X axis travel 8.66" Bed width 12.01" Main motor 10HP Spindle speed 3000 rpm Rapid traverse Z axis 394 IPM Rapid traverse X axis 295 IPM EQUIPPED WITH: -4-jaw universal 8"-chuck & set of toolholders -FANUC 21i-T CNC CONTROL (Powerful conversational programming capabilities) Approximate Floor Space Required 107" x 50" Approximate Machine Weight 6285 Lbs. STANDARD CONTROL FEATURES GE Fanuc G Code Operating System GE Fanuc/Romi Machine Guidance Programming Tool Path and Part Shape Graphic Display with 10.4" Color LCD Constant Surface Speed Background Editing and Sub-program Editing Canned cycles for Turning, Threading & Facing (G77, G78, G 79) Chamfering and Corner Rounding Canned Cycles for Drilling (G80-G89) Thread Repair Multiple Start Threading (G33) Rigid Tapping Manual Handle Feed MDI Operation Multiple Repetitive Cycle (G70-G76) G Code Family A,B & C Tool Nose Radius Compensation (G40, G41, G42) Tool Geometry and Wear Compensation 16 pairs Work Shift Inch/Metric Conversion Clock Function Run Hour and Parts Number Display Reader Punch Interface / RS 232 PCMCIA Slot for Flash Card Part Program Storage and Execution CNC Part Program Storage 64 Kbytes (160M) External Message Ladder Ladder Screen Visualization, Maintenance Alarms & Operating History English, Spanish, German or French Language Display. The M Series may be operated in any one of five ways: 1. Manually, using the X and Z hand wheels and the built-in DRO. 2. Manually, using the Manual Guidance hand wheel to move both axes simultaneously to cut radiUS and tapers. A box cycle is created and software limits can be set to insure precise size control for angles and radius. 3. Programs can be created by teaching the machine movements. 4. Programs can be created and the machine can be run using the Manual Guidance/Romi Conversational Program System. Rough and Finish Profiling, Threading, Grooving, Drilling and Tapping Conversational menus are used to generate part programs. 5. G code programming done off line or at the machine

Photos

|

Machinery

Inc. |