sales@1machinery.com

|

|

+1-819-346-2369 sales@1machinery.com |

Specifications

| Ask for quotation | |

| Stock ref. # 1744 |

|

|

Other specifications

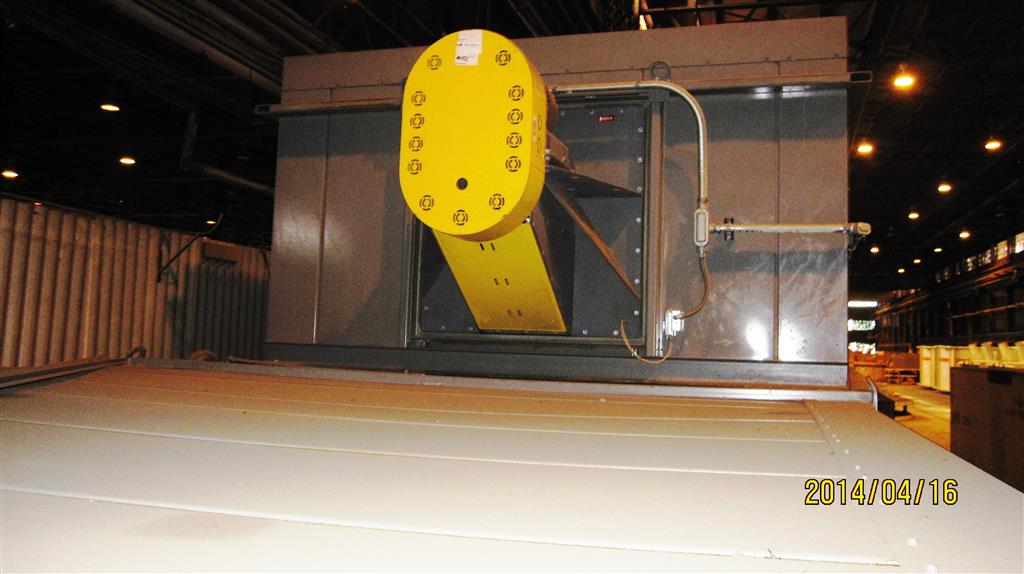

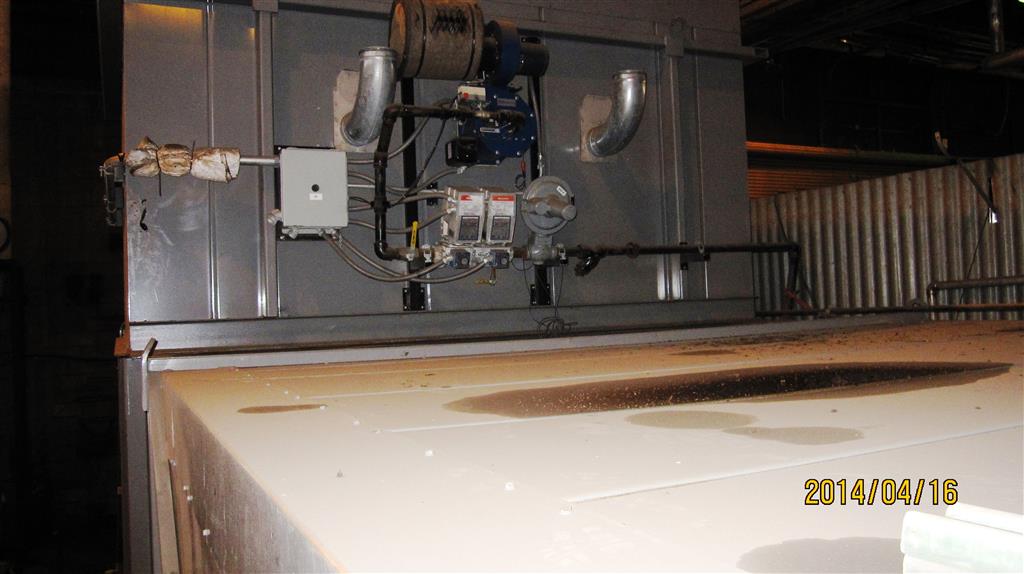

WISCONSIN OVEN MODEL BATCH 6/33/6-G8 NATURAL GAS FIRED WALK-IN SERIES OVEN MANUFACTURER: WISCONSIN OVEN CORPORATION YEAR: 2009 (HAS BEEN USED FOR LESS THAN 1 YEAR) MODEL BATCH 6/33/6-G8 S/N: 00550A0903 TEMPERATURE RATING: MAXIMUM - 800° F NORMAL - 375° F MINIMUM - 200° F ABOVE AMBIENT TEMPERATURE UNIFORMITY: ±10° F AT 375° F; CHAMBER DIMENSIONS: 6'0" WIDE X 33'0" LONG X 6'0" HIGH OVERALL (APPROXIMATE): 10'9" WIDE X 34'0" LONG X 14'9" HIGH OVEN BODY CONSTRUCTION: TONGUE & GROOVE PANEL ASSEMBLIES FEATURING OUR PATENTED HIGH EFFICIENCY PANEL SEAMS (PROVIDES 25% BETTER INSULATING EFFICIENCY) WITH 8" OF 6# DENSITY, SEMI-RIGID BATT TYPE INSULATION; 18 GAUGE ALUMINIZED INTERIOR; 20 GAUGE CARBON STEEL EXTERIOR; 12 GAUGE BASE AND ROOF TRIM OVEN DOORS: ONE (1) VERTICAL LIFT, PNEUMATICALLY OPERATED DOOR WILL BE PROVIDED AT EACH END OF THE OVEN; THE AIR CYLINDERS ARE PERMANENTLY LUBRICATED AND THE FILTERREGULATOR IS INCLUDED; HAND VALVE FOR THE DOOR LOCATED ON THE SAME SIDE AS THE CONTROL PANEL; MANUAL SAFETY LATCH PROVIDED TO SECURE EACH DOOR IN OPEN POSITION FOR MAINTENANCE; DOOR LIMIT SWITCH PROVIDED TO SHUT BURNER TO LOW FIRE WHEN DOORS BEGIN TO OPEN OVEN FLOOR: REINFORCED INSULATED FLOOR (6" THICK) WITH WHEEL GUIDES, CONSISTS OF THREE (3) INSULATED PANEL SECTIONS WITH TWO (2) 12 GAUGE "U" CHANNELS SPACED ON 56" CENTERS (PLEASE ADVISE IF DIFFERENT) LOCATED BETWEEN THE PANELS TO GUIDE WHEELS OF A LOAD CAR RECIRCULATION: 37,200 CFM @ 30 HP PLUG MOUNTED BLOWER • END AIRFLOW • HIGHER EFFICIENCY MOTOR • SUPPLY AIR WILL BE DELIVERED THROUGH FULLY ADJUSTABLE BOXED DUCTS (LOUVERED OPENINGS ARE FACTORY PRESET), SIDE-MOUNTED ALONG THE LENGTH ON EACH SIDE OF THE WORK CHAMBER, AT ONE END OF THE WORK CHAMBER • RETURN AIR WILL BE RETURNED TO THE RECIRCULATION AND HEATING PLENUM THROUGH A FULLY ADJUSTABLE RETURN DUCT LOCATED AT THE OTHER END OF THE WORK CHAMBER • AIRFLOW SAFETY SWITCH (PROOF-OF-BLOWER OPERATION) EXHAUST: MANUALLY ADJUSTABLE, DAMPERED OUTLET LOCATED ON THE PRESSURIZED SIDE OF THE RECIRCULATION SYSTEM FOR POSITIVE VENTING; OVEN NOT RATED FOR CLASS A USE (AS DEFINED BY NFPA 86) WHERE SOLVENTS, VOLATILES, OR POWDER CONSTITUENTS ARE PRESENT; EXHAUST STACK NOT INCLUDED HEATING EQUIPMENT: INDUSTRIAL AIR HEAT BURNER RATED AT 1,500,000 BTU PER HOUR; PIPED COMPLETE, INCLUDING THE FOLLOWING ITEMS: • COMBUSTION AIR BLOWER, COMPLETE WITH COMBUSTION AIRFLOW SWITCH • COMBUSTION FILTER • DIRECT SPARK IGNITED WITH SHUT-OFF VALVE • GAS LINE FILTER/STRAINER AND MAIN GAS PRESSURE REGULATOR • GAS SHUT-OFF BALL VALVES AND HIGH/LOW GAS PRESSURE SWITCH • MOTORIZED (MODULATING) GAS CONTROL VALVE • MOTORIZED SHUT-OFF, BLOCKING VALVES AND LEAK TEST ARRANGEMENT • FLAME DETECTOR & FLAME RELAY WITH ALARM HORN, RED LIGHT, AND SILENCING RELAY CONTROLS AND INSTRUMENTS: LOCATED IN AN OVEN MOUNTED, NEMA 12 ENCLOSURE, MOUNTED ON THE RIGHT SIDE OF THE OVEN, INCLUDING THE FOLLOWING ITEMS: • DIGITAL HONEYWELL DCP 100 PROGRAMMABLE TEMPERATURE CONTROLLER (WITH AUTOTUNE) • DIGITAL BARBER-COLMAN 7SL OVEN HIGH LIMIT CONTROLLER (WITH MANUAL RESET) • HONEYWELL DR4300 10" CIRCULAR CHART RECORDER W/ 1 PEN & DIGITAL DISPLAY • IEC STYLE MOTOR STARTERS, PUSH BUTTONS AND PILOT LIGHTS (TO INDICATE STATUS), FUSED BRANCH CIRCUITS, 110 VOLT CONTROL TRANSFORMER AND BLOWER INTERLOCKS • HONEYWELL MODEL 7800 FLAME RELAY WITH INTEGRAL PURGE TIMER • MAIN POWER DISCONNECT SWITCH NON-POWERED LOAD CART: 5'4" WIDE X 25'0" LONG X 1'0" HIGH; CARBON STEEL STRUCTURE; 1,000 POUND CAPACITY; CAR WILL RIDE ON V-GROOVE WHEELS, TWO (2) SWIVEL & TWO (2) FIXED; REMOVABLE HANDLE UTILITY REQUIREMENTS: • ELECTRICAL - 480 VOLT, 3 PHASE, 60 HERTZ • NATURAL GAS - 1,000 BTU PER CUBIC FOOT AT A CONSTANT PRESSURE OF 1-5 PSIG • COMPRESSED AIR - 100 PSIG; FILTER-REGULATOR INCLUDED LOCATION: MONTREAL,QUEBEC, CANADA

Photos

|

Machinery

Inc. |